Option 1. Across the Foredeck (Richard Leftley [115])

Attach a small block (1) as close as possible to the bow – I used a zip tie through the loop of the forestay rope. Then tie a thin rope to the shackle used to attach the forestay and run the rope through the block (1) on the bow attaching a second small block (2) to the end of this rope. This block (2) is used to give a 2:1 purchase because a 1:1 will not give enough movement on the bungee cord to be able to calibrate accurately. Run a second thin rope from the mast foot through the block (2) and back toward the mast foot attaching it to a short length of shock cord which is tied off also on the mast foot. Set the calibration so that with your maximum rig tension pulled on the shock cord is slack, as you let off rig tension the shock cord will be pulled tighter and move down the foredeck away from the mast. Mark the foredeck with a calibration such that it provides for maximum and minimum rig tension! Its also important that the length of shock cord is long enough to allow the rig tension to be eased sufficiently in light wind without the shock cord fighting against you.

Option 2. In-Cockpit Version (Alistair Glen [126])

Original FB Post below –

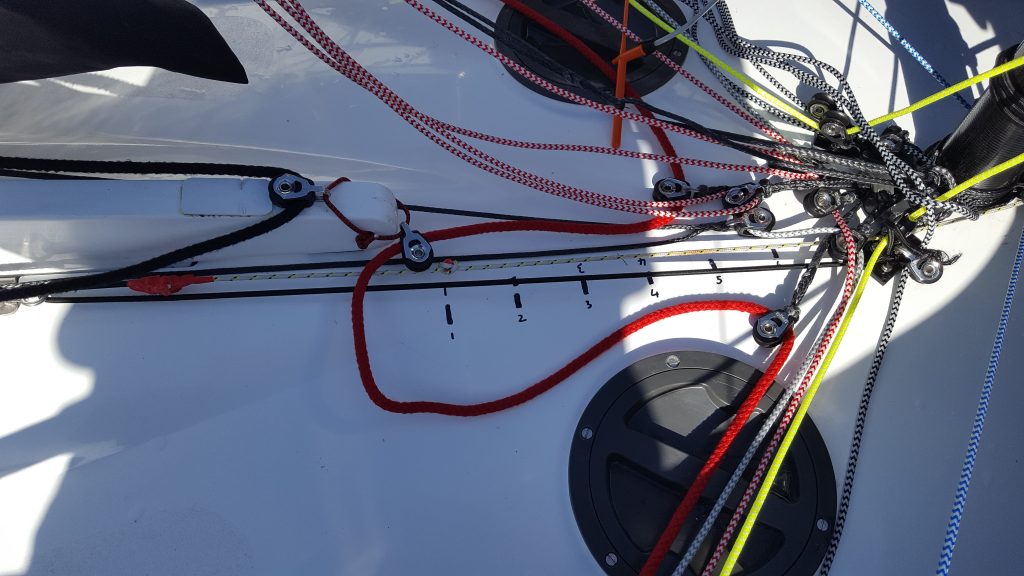

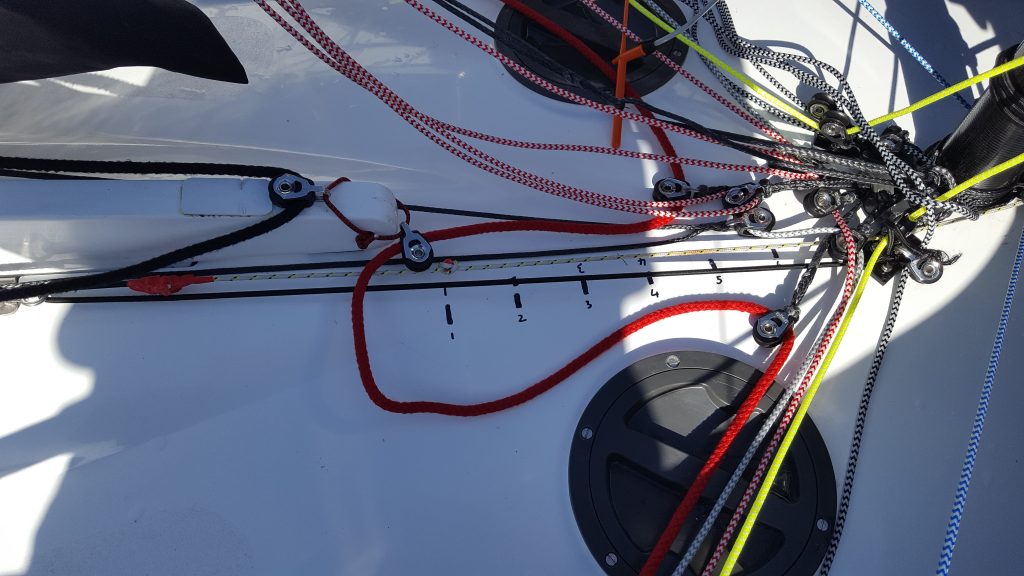

Rake Adjustment Calibration – I wanted to try it out in a ‘meaningful’ breeze to check that it worked. One end of the string is attached to the double block under the foredeck and then led aft through the inner of the two deck clips holding the blocks at the foot of the king post. Add a bobble or knot as a reference point. Then attach shock cord to the end and run this through a ring/small block attached to a P-clip held by the centreboard stirrup screw. Run the end of the shock cord forward to the other deck clip and tie off at a suitable tension. Set rig to your upright/max tension position, fiddle with knot/bobble, make some calibration marks and Bob is, as they say, your Mother’s brother! Last night I was sailing in 15-20kts and my rake never got as far off as ‘3’ on my scale – ‘6’ is just as you realise the forestay shackle has let go! WORD OF WARNING – the 1/2″ self-tapper retaining my stirrup was only holding on the last turn and a half so make sure that you have a 3/4″ self-tapper of the same diameter and/or the next gauge up. I’m not going to say you need an 8 or 10; Chinese quality control is so poor that I’ve got 8s of three different diameters in my tool box! If you do end up drilling through the block, don’t despair but add plenty of sealant to preserve watertight integrity. P.S. The line that looks like a crack emanating from the stirrup isn’t…but I did rush out to check when I saw the photo this morning!